WATER TREATMENT WITH MPR - MULTI-PHASE REACTOR

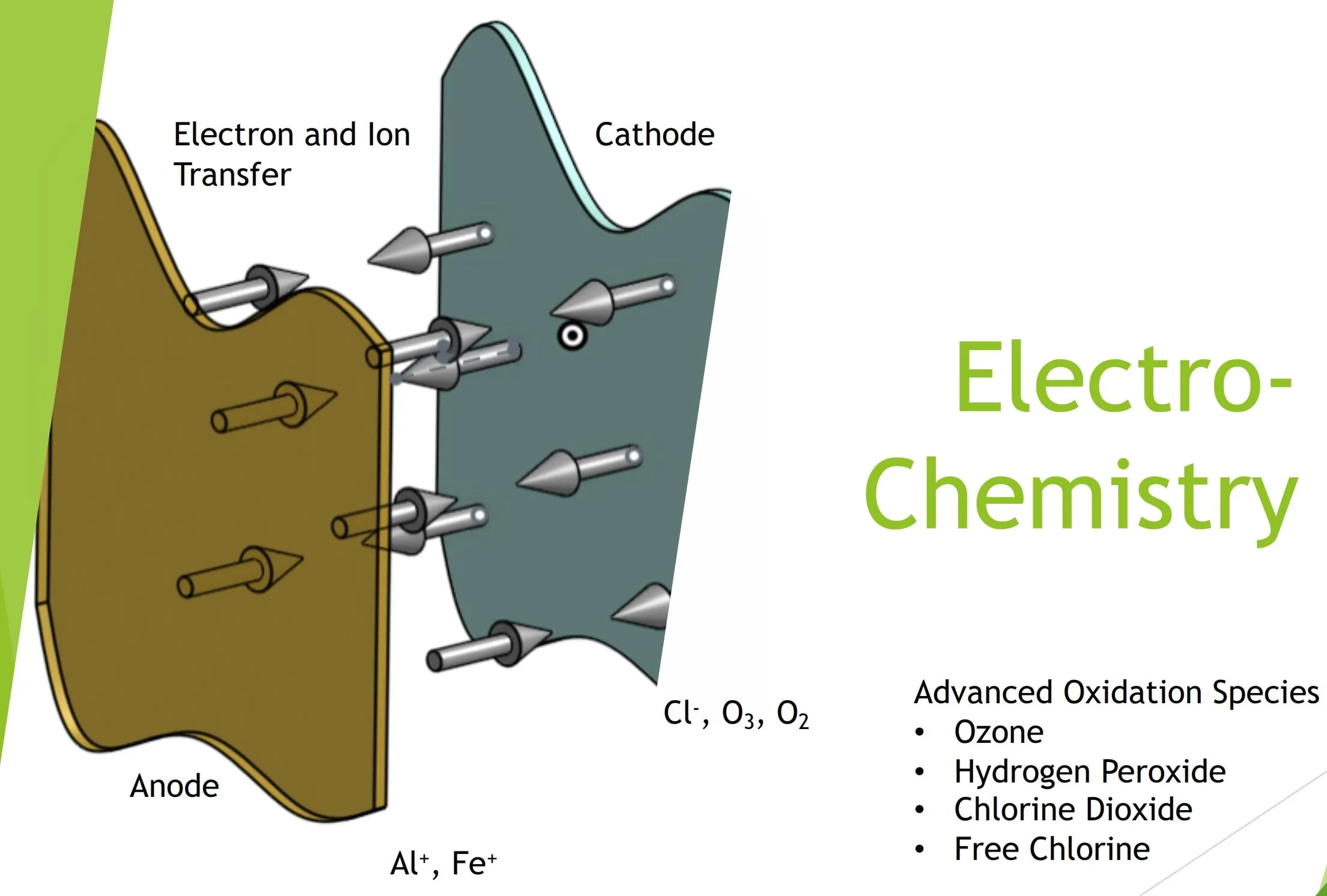

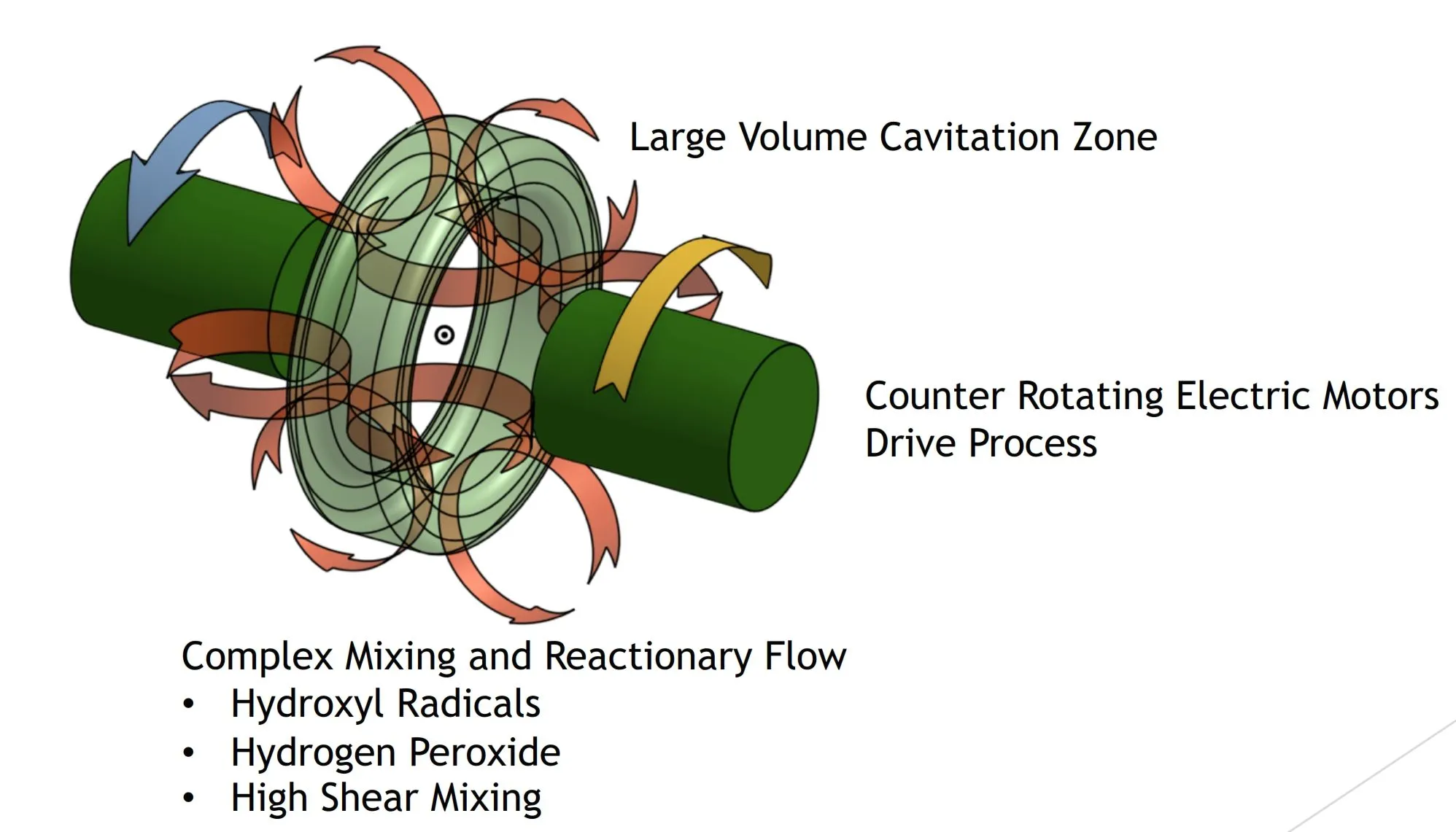

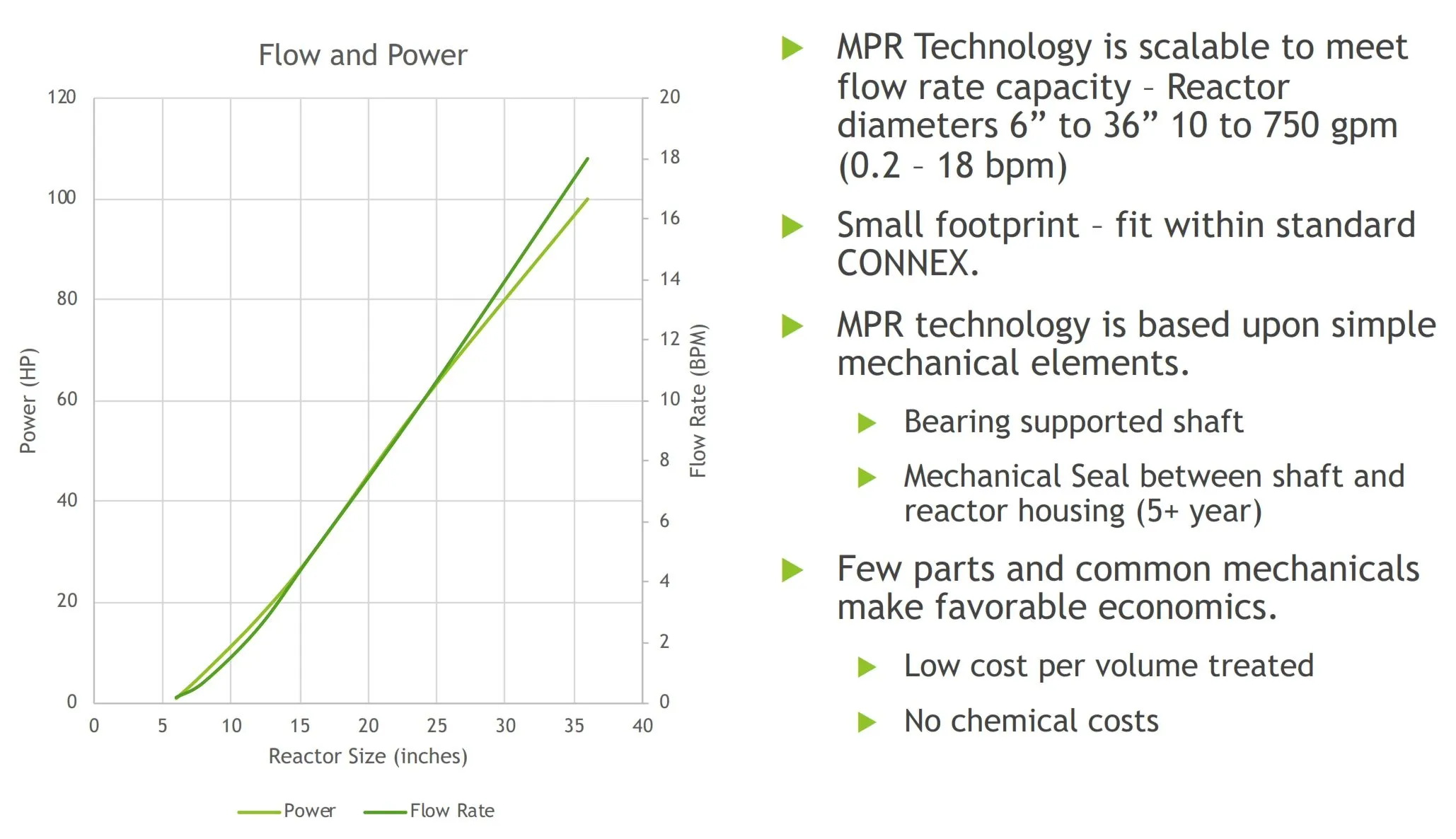

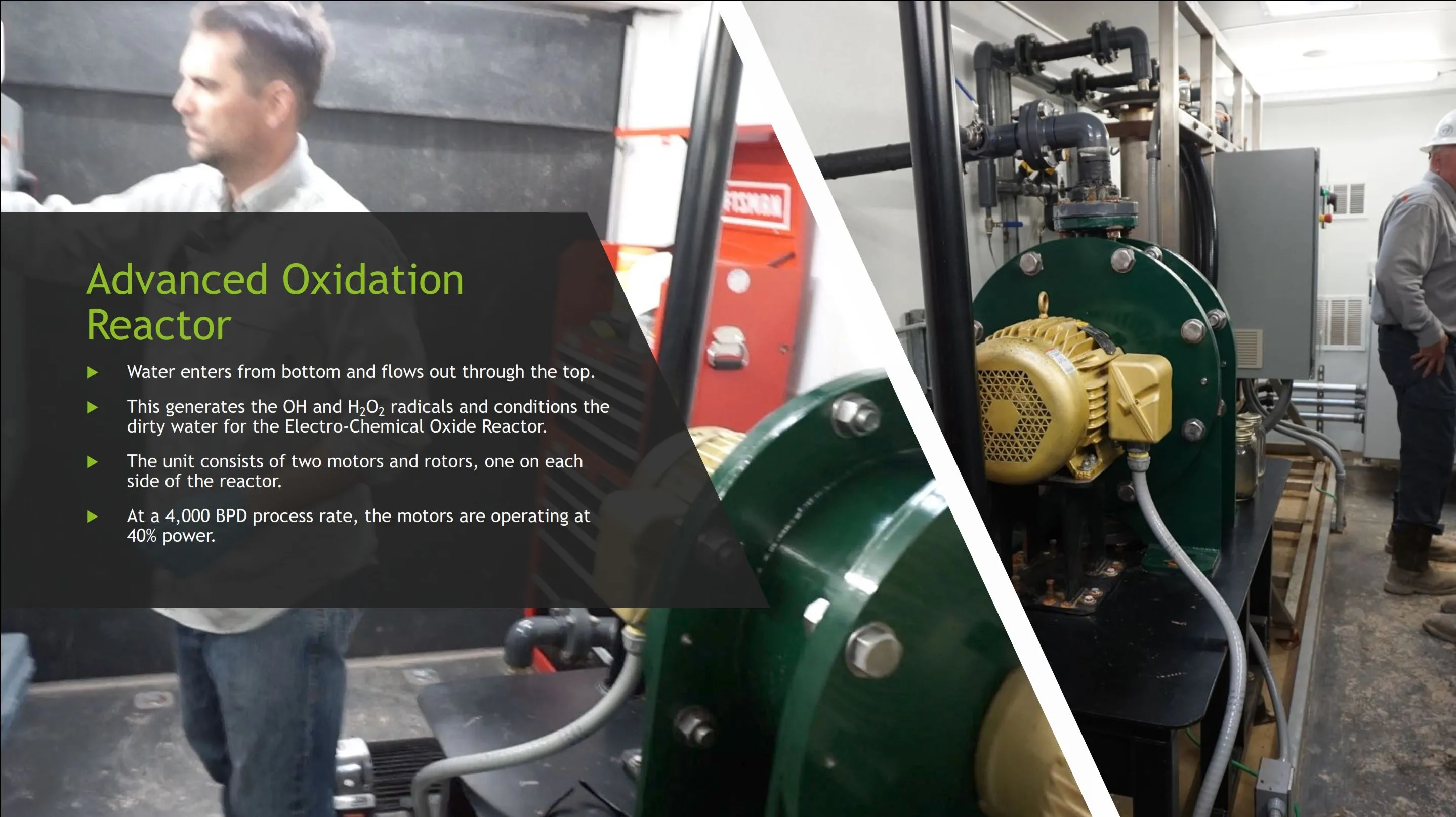

The Complus Trading North America LLC Multi-Phase Reactor is an advanced oxidation process that creates highly reactive oxidizing radicals directly from the wastewater stream without requiring additional chemicals or precursor oxidizers.

Suspended biosolids in the wastewater are significantly reduced in particle size through the lysing of cellular matter, followed by oxidation of the resulting smaller particles. This process alone can fully sterilize the water, enhancing the bio-reactivity of solids entering the digester and shortening digestion time.

Dissolved solids, such as metal ions, are oxidized, where the metal ions bond with oxygen, becoming insoluble. These insoluble materials form solid precipitates that are removed through conventional filtration. Chlorides previously bonded to the metal ions transform into chlorine dioxide and free chlorine.

SUMMARY OF TECHNOLOGY

Modular and scalable for high-volume production, it effectively eliminates contaminants and microbes, desalinates water, and produces drinking water that meets US EPA guidelines from any source. It is low maintenance, field-tested, commercially proven, and equipped with online monitoring and data logging capabilities.

APPLICATIONS

-

MPR treated biosolid loaded water break down the bio-solids reducing the solidscontent in the effluent by up to 80%

- Proven to lower BOD and COD by 90 – 95%

- 85 – 90% Removal of Nitrogen

-

Break down of filamentatous bacteria and release of intracellular matter thatincreases biological reactivity, reducing digestor exposure time to hours instead ofdays.

-

Ozone is organically generated within the MPR is highly effective in sterilizinginfluent. Remove competitive and hazardous biologics (bacteria, virus, and spores)from entering digestor. Improved quality of clarified effluent and recovered solids.

-

Bio-Solids discharged from clarifier much lower in volume and classified as Class A,suited for direct disposal.

Treatment of VOCs, TSS, TDS

-

- MPR cavitation and electro-chemistry provide perfect storm of advanced oxidation

radicals that:- Wet Oxidation of VOCs, converting to products of combustion (high concertation of

Advanced Oxidation species decomposes VOCs) - Expose TDS to oxidation species, converting to insoluble solids, e.g. Fe(+) to FexOy, H2S to

SxOy, etc. - Raise ORP >300

- Wet Oxidation of VOCs, converting to products of combustion (high concertation of

- High Shear fractures long chain organics (hydrocarbons, pharmaceuticals,

polymers, etc) and solids (minerals).

- MPR cavitation and electro-chemistry provide perfect storm of advanced oxidation

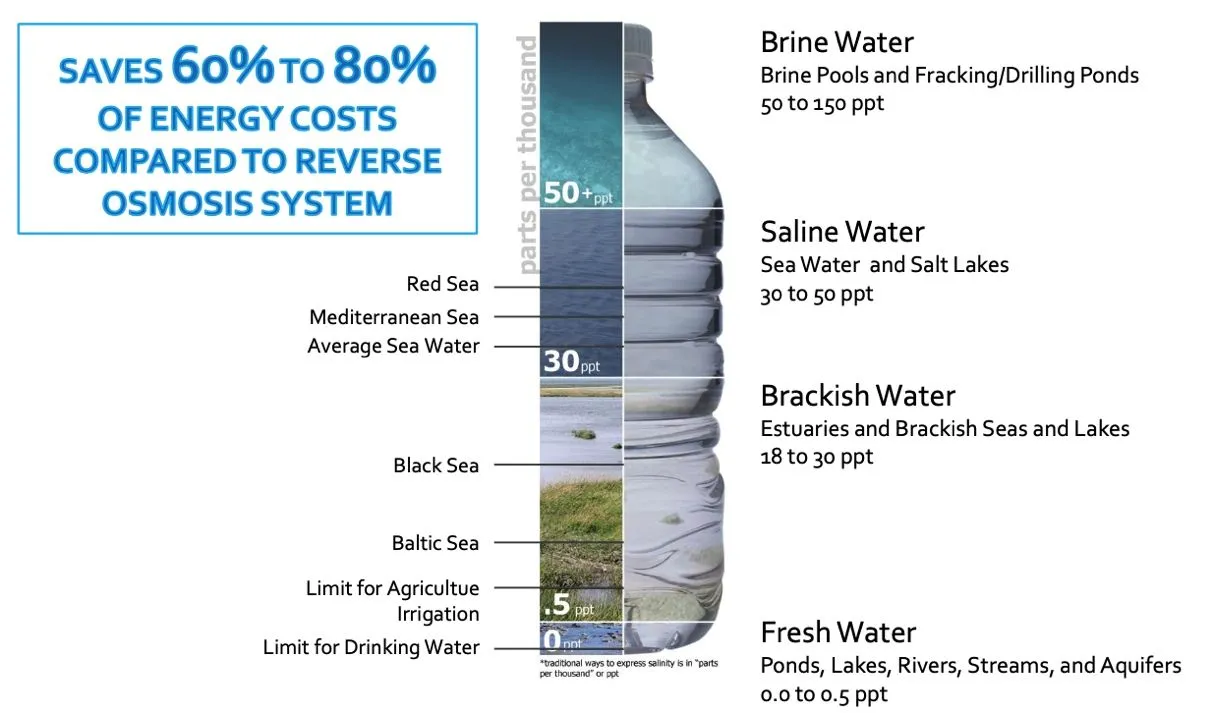

Approach 1 – Desalination via physical chemistry

- Cavitation and Electo-Chemical reaction to Oxidize TDS to insoluble mineralized

oxides - Halides no longer have corresponding (+) ion to associate with. Becomes Free

Chlorine, ClO2, other

Approach 2 – Vapor Distillation

- Cavitation, exothermic reaction of VOCs, and Frictional heating raises water

temperature to boiling point. - High efficiency of heating – non-scaling

- Flash distillation of water vapor

- Vapor condenser pre-heat feed water.

- Energy balance very favorable relative to other phase change processes.

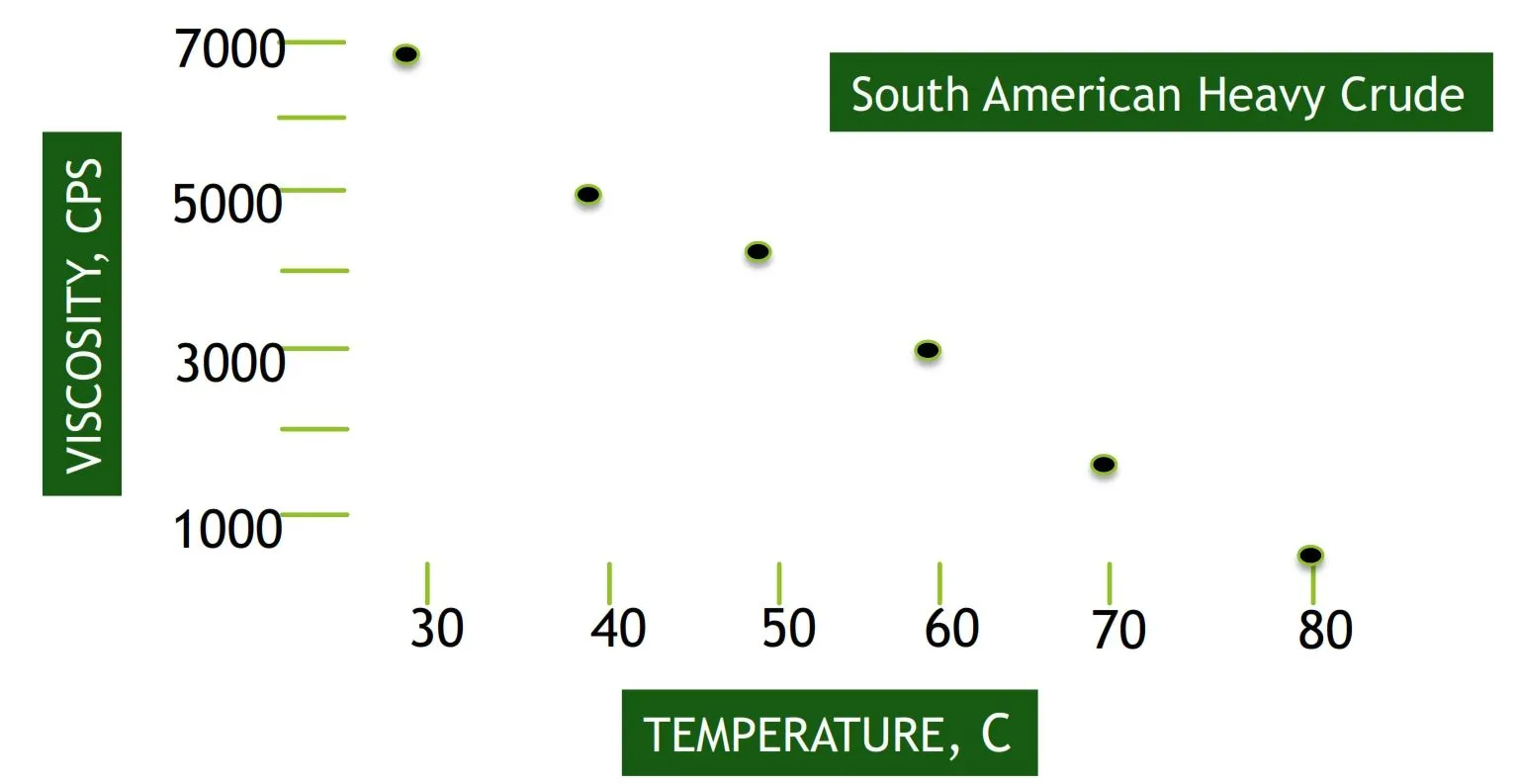

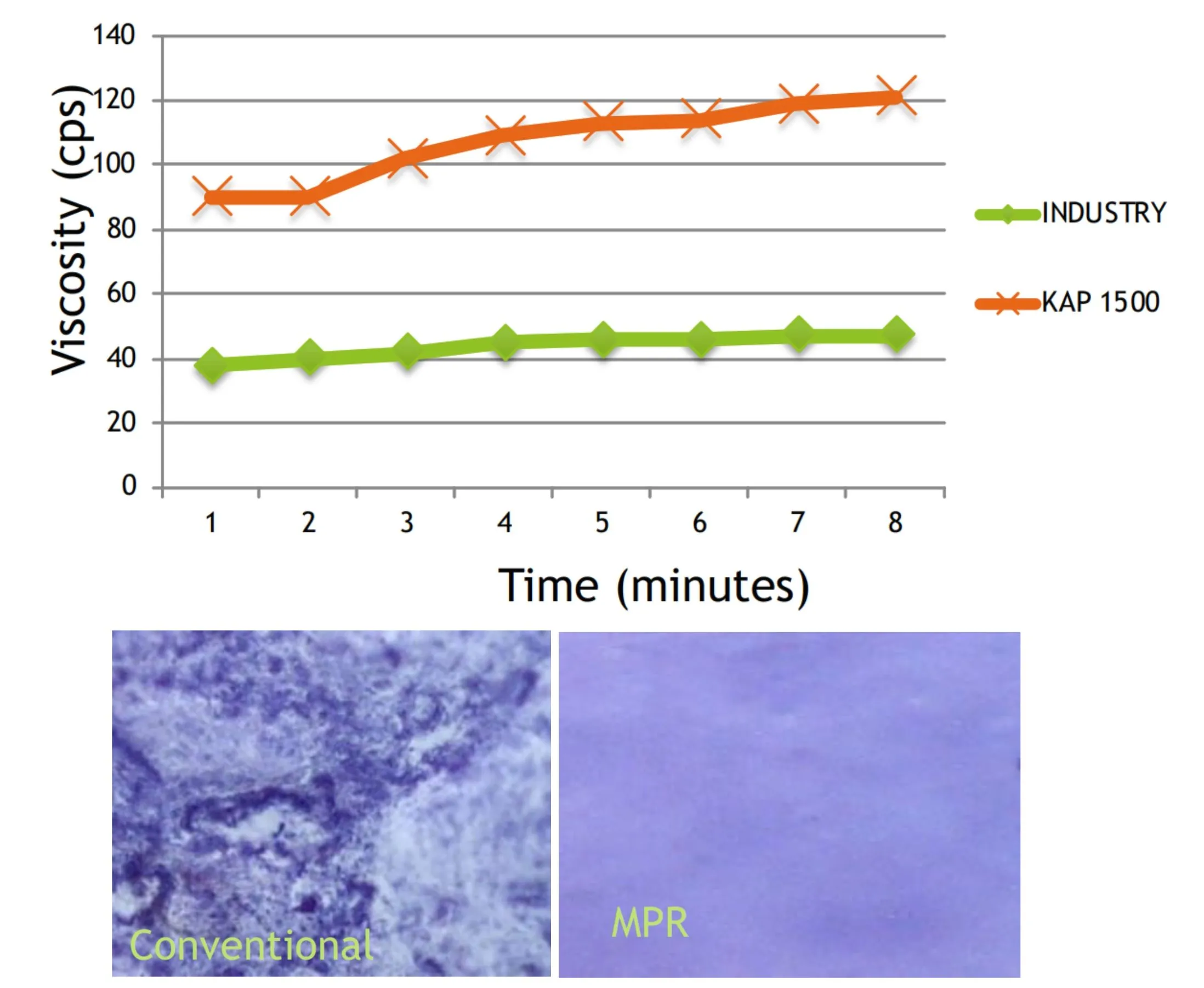

- MPR technology produces high shear in crude

- Frictionally heats oil

- Fractures long chain hydrocarbon

- Creates C10 – C15 distillates

- Permanently lowers viscosity, no further heating required for down stream processing.

- MPR technology produces high shear in crude

- Frictionally heats oil

- Fractures long chain hydrocarbon

- Creates C10 – C15 distillates

- Permanently lowers viscosity, no further heating required for down stream processing.

- Proven high performance extraction with:

- Oils - CBD, Olive, Hops, Peppers

- Proteins - Chicken Biomass

- Protein/Oils/Nutrient brought into solution by breaking cellular structure, not

necessarily cavitation which can cause radical formation in extraction

product. - Water extraction yields higher quality and purity, simple and low-cost

processing techniques- No hydrocarbon solvents to extract

- No technical complexity with supercritical fluids

- Retain micro-nutrients lost via conventional extraction

APPLICATIONS

Call us for any querry

US +1 (830) 200 5119

EU +39 02 8719 9397

Share our website

Please share our website on your social medias. THANKS !!!